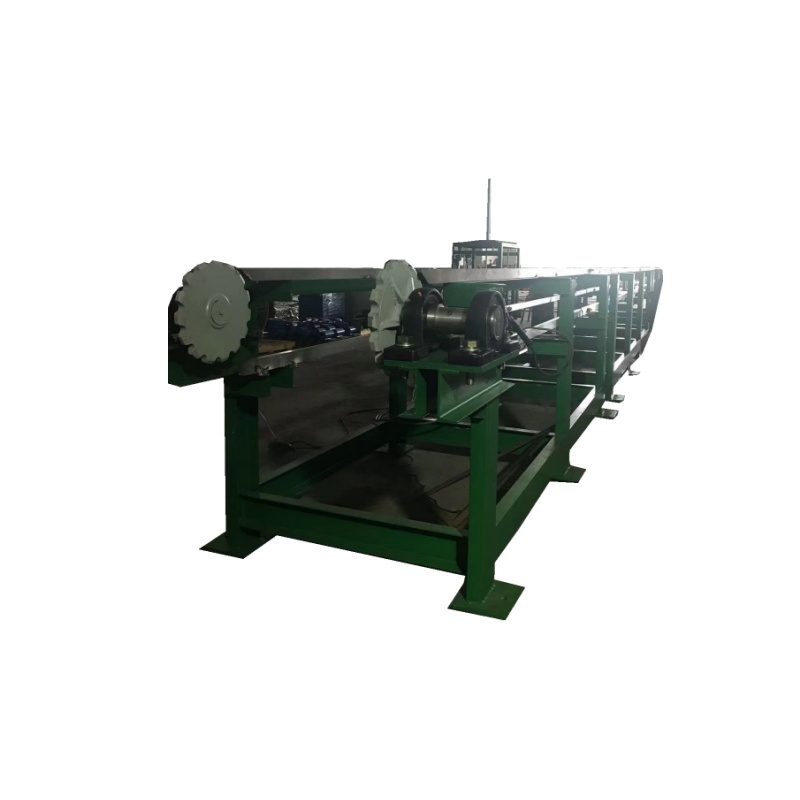

<p>lead cathode plate making machine lead cathode casting machine lead electrolysis machine system</p>

<p class="p"><span style="mso-spacerun: 'yes'; font-family: Calibri; mso-fareast-font-family: 宋体; mso-bidi-font-family: 'Times New Roman'; font-size: 12.0000pt; mso-font-kerning: 0.0000pt;">Lead cathode plate automatic line</span></p>

<p class="p"><span style="mso-spacerun: 'yes'; font-family: Calibri; mso-fareast-font-family: 宋体; mso-bidi-font-family: 'Times New Roman'; font-size: 12.0000pt; mso-font-kerning: 0.0000pt;">The lead pump preheats the circulating lead in the lead storage tank, gradually increasing the molten lead level in the tank, allowing the production drum to be immersed in an appropriate amount of lead liquid. As the drum rotates, a layer of lead liquid is adhered to the surface of the cylinder, which solidifies into a thin layer of lead skin. During the drum rotation process, it is peeled off by a shovel, and under the action of its own weight, it enters the shear device along the guide plate of the bracket, and is cut to length during the travel process, Pieces of lead skin are transported by the feeding device to the next station for waiting. At the same time, the feeding device sends copper bars one by one through the feeding plate of the feeding device to wait at that station. When the lifting device is working, the copper bars are lifted, and the lead skin (at this time, the cutting center of the lead skin should coincide with the center of the copper bar) is bent and wrapped around the copper bar under the action of the rising copper bar. When the starting plate is at the pressing device and leveling device, it is driven by the hydraulic cylinder, Complete the leveling of the starting plate, lift the finished starting plate onto the chain of the pushing device by the lifting chain, and arrange it according to the predetermined spacing. When the electrolytic cell needs to be loaded into the starting plate, a dedicated hanger can be used to lift it from the slot arrangement device and directly load it into the slot.</span></p>

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy