Lead acid battery Recovery auxiliary system mainly includes: lead paste pre desulfurization, neutralization treatment of acid solution, sodium sulfate solution purification system, sulfur sulfate crystallization system, etc. Due to the acid environment system, the requirements for each system are very high, so the higher the degree of automation, the better

PLC centralized control mode is adopted in the whole system, with two working states of full-automatic and manual, which is more convenient for operation and management. Each actuator is equipped with manual buttons on the control cabinet to facilitate debugging, maintenance and ensure normal production in case of automatic failure. In order to ensure the absolute safety and reliability of the control cabinet, the main control electrical products are world-famous high-end products (the main control electrical products are Schneider, the PLC brand is Siemens, and the instruments are international and domestic well-known brands, such as GF, coreda, chengci, etc.); The control cabinet provided can meet the ambient temperature (-10 ℃ - +50 ℃) and the vibration requirements of the support structure, and comply with ip52 standard (for indoor installation) and relevant specifications; The design, material selection and strength of the control cabinet meet the requirements of national standards and specifications, and the internal and external surfaces are smooth and tidy; The control cabinet is equipped with ventilation device to ensure that the internal temperature during operation does not exceed the limit value of the allowable temperature of the equipment; Power switch, standard socket and lighting lamp are set inside the control cabinet; The metal structural parts in the panel, table and cabinet are firmly and reliably grounded, and independent PLC DC ground, chassis safety ground, cable shielding ground contact terminals and structures are set, which are electrically isolated from the internal ungrounded circuit board.

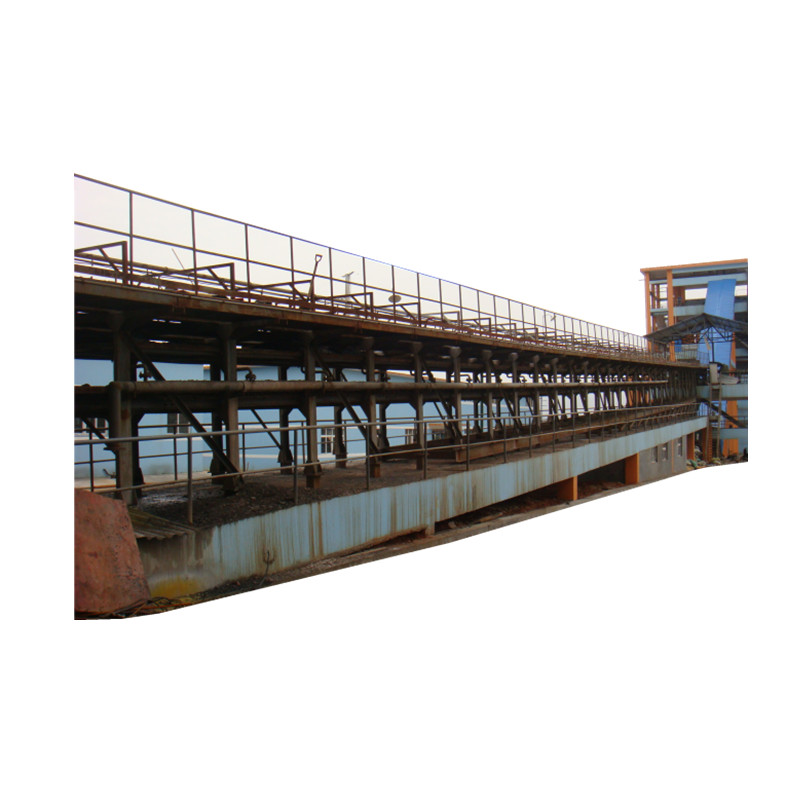

Lufeng has rich experience and can meet the project needs of customers with different processing capacity.

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy