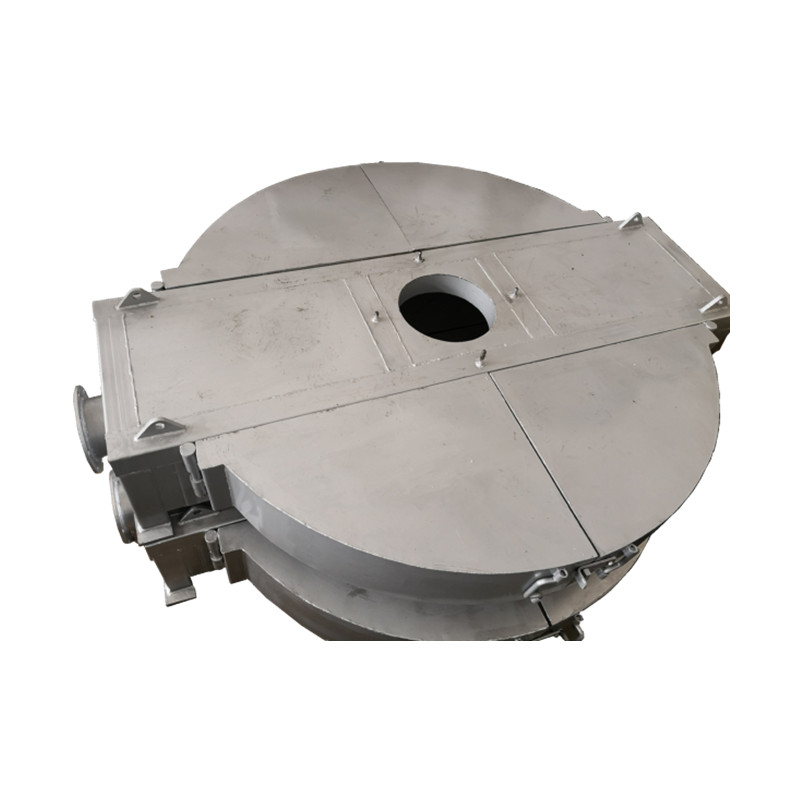

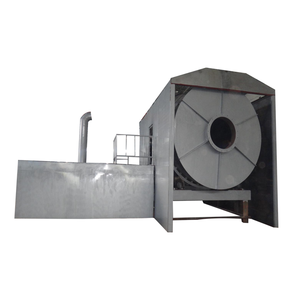

200kg induction heating machine for metal forging industrial melting furnace

An induction furnace

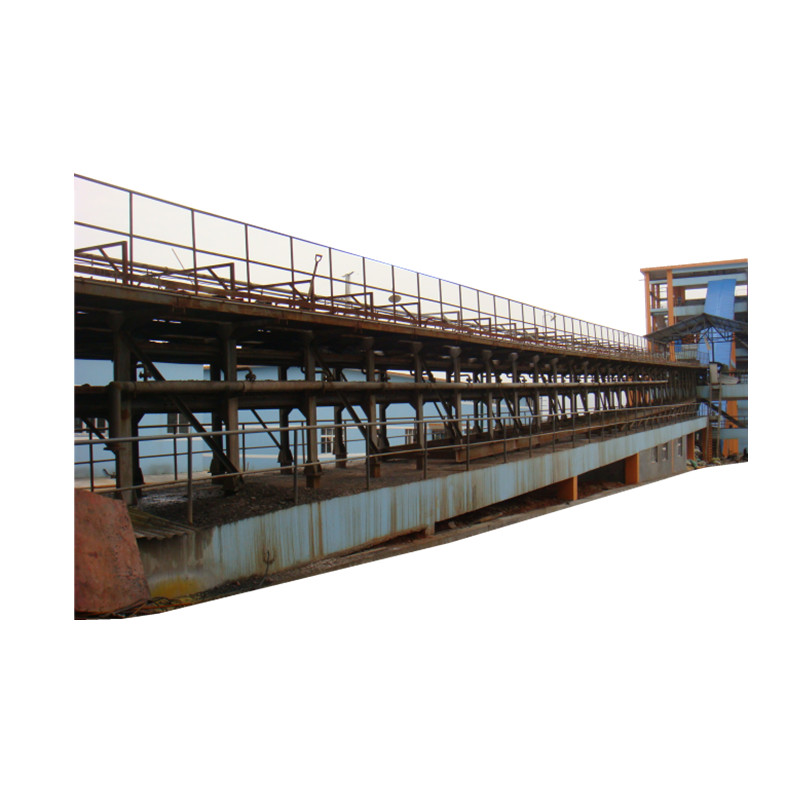

An induction furnace with a frequency range of 150 to 10000 Hz is called an intermediate frequency induction furnace. The medium frequency induction furnace is a special smelting equipment suitable for smelting high-quality steel and alloys. It has advantages such as fast melting speed, high production efficiency, strong adaptability, flexible use, good electromagnetic stirring effect, convenient start-up operation, and steel liquid being covered by slag (reducing atmospheric pollution of steel liquid). The complete equipment of the medium frequency induction furnace includes: power supply and electrical control part, furnace body part, transmission device, and water cooling system.

The medium frequency induction furnace is particularly suitable for large, medium, and small furnaces with a capacity of tens of tons of 10kg. It is used for melting steel, cast iron, copper, aluminum, and other non-ferrous metals and their alloys, as well as insulation of liquid metals. It has strong adaptability to furnace materials and is suitable for intermittent operations. The furnace structure and usage are similar to those of a power frequency coreless induction furnace. Since the 1970s, with the increasing power and reliability of high-efficiency, static, and metal saving thyristor intermediate frequency power supplies, intermediate frequency furnaces have developed rapidly both domestically and internationally. They not only have obvious advantages in small and medium-sized capacity, but also are replacing industrial frequency heartless induction furnaces in large capacity. [1]

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy