<p>xiangtan lufeng machinery company high temperature lead or zinc liquid transfer pump for sale</p>

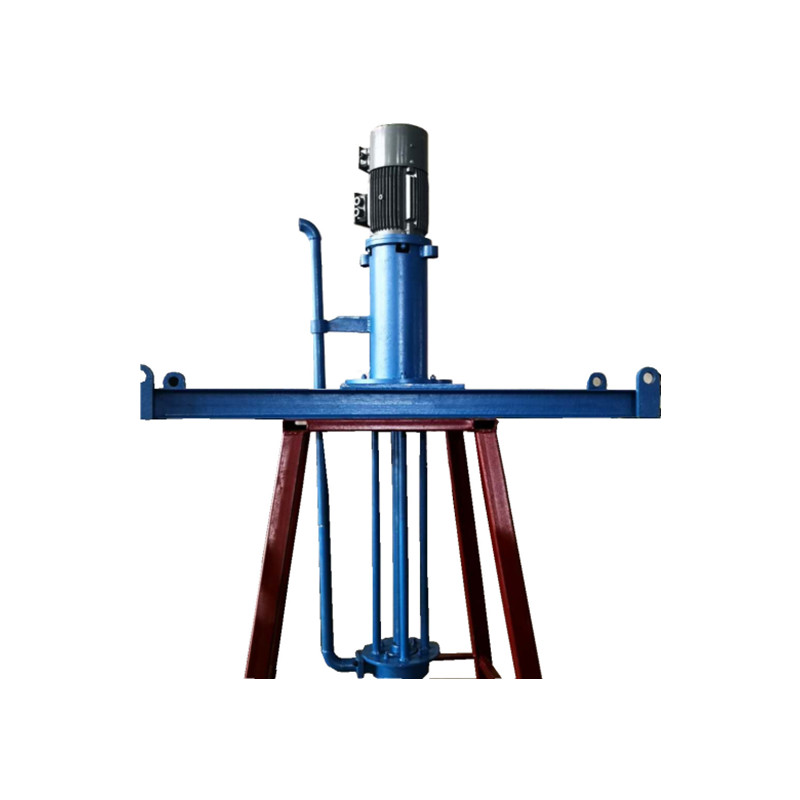

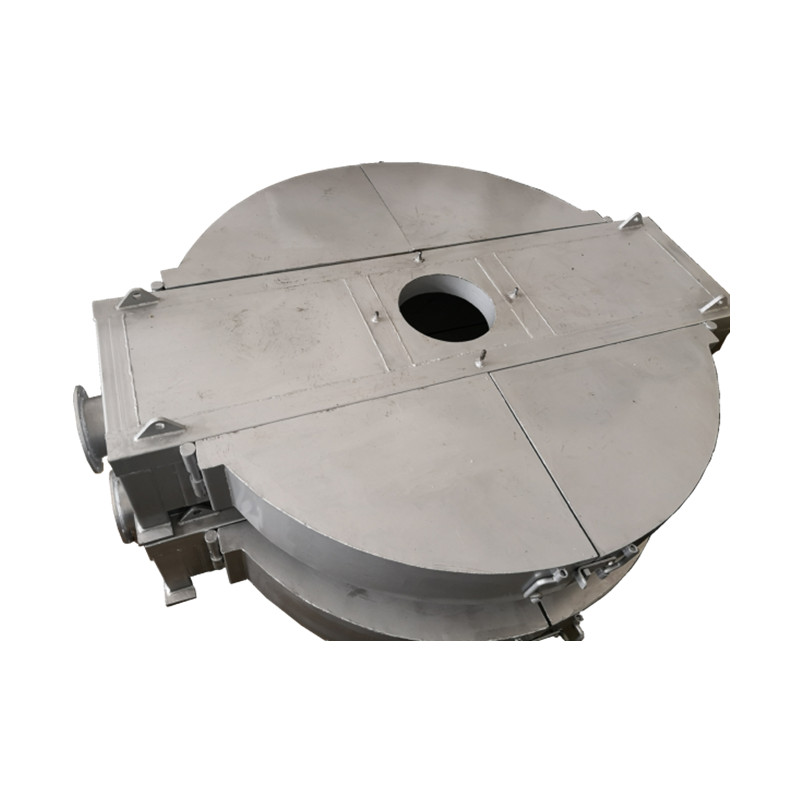

<p class="p"><span style="mso-spacerun: 'yes'; font-family: 宋体; mso-ascii-font-family: Calibri; mso-hansi-font-family: Calibri; mso-bidi-font-family: 'Times New Roman'; font-size: 12.0000pt; mso-font-kerning: 0.0000pt;"><span style="font-family: Calibri;">Lead liquid pump </span></span></p>

<p class="p"><span style="mso-spacerun: 'yes'; font-family: 宋体; mso-ascii-font-family: Calibri; mso-hansi-font-family: Calibri; mso-bidi-font-family: 'Times New Roman'; font-size: 12.0000pt; mso-font-kerning: 0.0000pt;"><span style="font-family: Calibri;">Lead water pump is a pump used in lead processing enterprises to extract high-temperature liquid lead. It belongs to a type of centrifugal pump. The impeller is an open impeller</span><span style="font-family: 宋体;">。</span></span></p>

<p class="p"><span style="mso-spacerun: 'yes'; font-family: 宋体; mso-ascii-font-family: Calibri; mso-hansi-font-family: Calibri; mso-bidi-font-family: 'Times New Roman'; font-size: 12.0000pt; mso-font-kerning: 0.0000pt;"><span style="font-family: Calibri;">The detailed requirements and assembly requirements for all spare parts of the complete lead pump include the pump body bottom plate, pump body, valve, valve guide rod, valve core, lead pump blade, lead pump shaft sleeve, lead pump wear sleeve, etc. The lead pump wear sleeve adopts a spiral wear resistant design, and the lead pump design has a reflux function. Excess lead liquid can be returned to the lead pot. The lead pump valve is designed with a heating pipe to prevent cooling blockage during the lead liquid transportation process.</span></span></p>

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy