PRODUCT NAME:

copper smelting blast furnace ore melting furnace industrial metal melting furnace

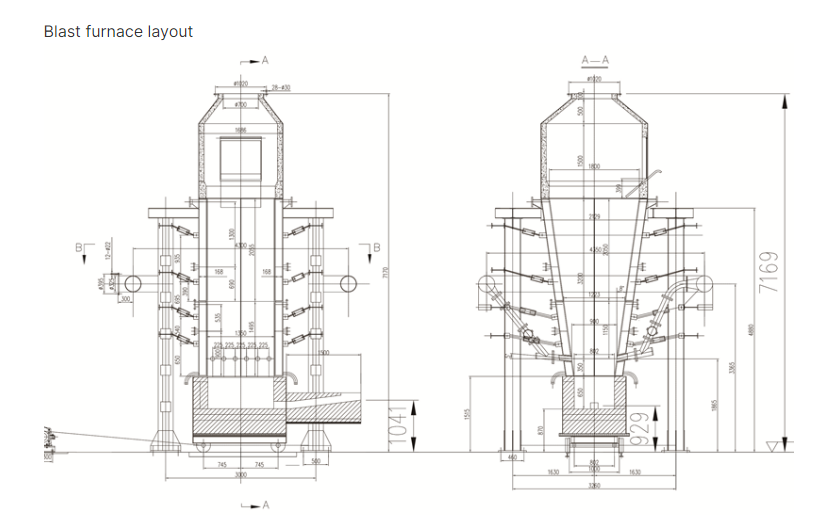

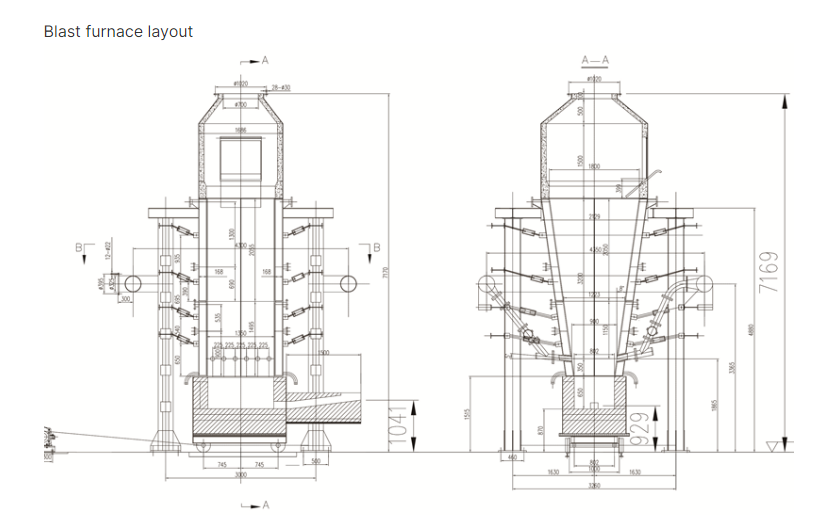

Blast furnace function

Blast furnaces can be used for matte smelting of metals such as copper, nickel, cobalt, and reduction smelting of metals such as lead and zinc. They can also be used for melting miscellaneous copper and processing other materials. The charge of a blast furnace is generally block shaped, and the fuel is coke. The furnace materials are added in batches from the top of the furnace to form pillars. Air is blown in from the lower tuyere, and coke burns in the tuyere area, forming a high-temperature melting zone; The furnace material reacts fiercely here and continuously melts. During reduction smelting, the melt clarifies in the furnace hearth, releasing metal and slag separately. During matte smelting, the melt flows into the front bed through this bed, clarifying and separating matte and slag. During the process of hot flue gas passing through the furnace material and rising to the furnace top for discharge, the furnace material is preheated (during smelting and kneading of concentrate, it also causes the concentrate to sinter), and partial smelting chemical reactions occur. So the blast furnace has good heat and mass transfer conditions, high thermal efficiency, and a large daily production capacity per unit area (i.e. bed energy rate).

PRODCUT PICTURES:

copper smelting blast furnace ore melting furnace industrial metal melting furnace

copper smelting blast furnace ore melting furnace industrial metal melting furnace

copper smelting blast furnace ore melting furnace industrial metal melting furnace

SPECIFICATIONS:

copper smelting blast furnace ore melting furnace industrial metal melting furnace

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy