PRODUCT NAME:

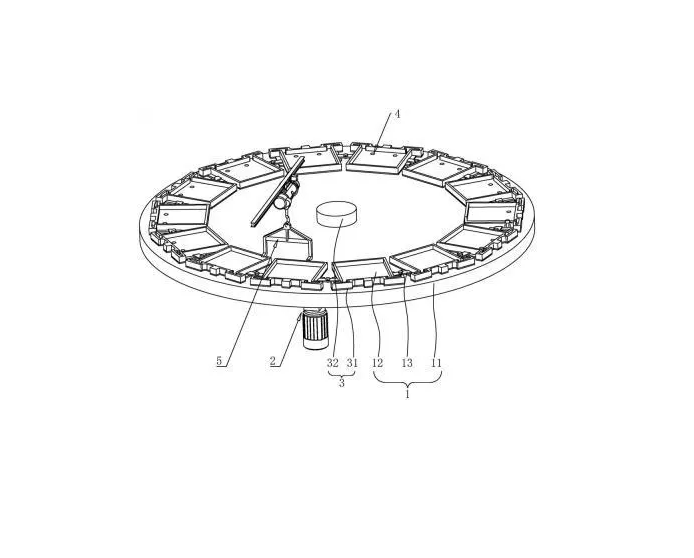

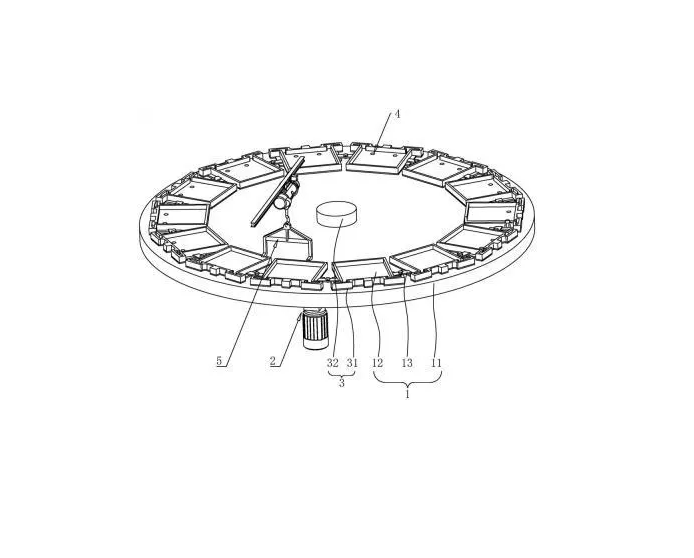

copper concentrate refining electrolysis system anode electrolytic round disc plate casting machine

The processing process of lead-zinc ore usually includes the following main steps:

1. Mineral processing: Lead zinc ore is selected and graded to select ore with high lead and zinc content.

2. Crushing and grinding: The selected lead zinc ore is subjected to crushing and grinding operations to make its particle size suitable for subsequent processing.

3. Flotation: Flotation operations are carried out on the crushed and ground lead-zinc ore, utilizing the differences in density, buoyancy, and surface properties between lead-zinc ore and other minerals to obtain lead concentrate and zinc concentrate.

4. Separation: separate the flotation lead and zinc concentrate, including flotation foam separation, centrifugal separation and gravity separation, to obtain pure lead concentrate and pure zinc concentrate.

5. Reflotation: Perform a reflation operation on zinc concentrate to further improve zinc grade and extraction rate.

6. Smelting: Place pure lead concentrate and pure zinc concentrate into a furnace for high-temperature melting, allowing the lead and zinc to melt separately and obtain pure lead and zinc ingots.

7. Refining: Further refining of lead and zinc ingots, including smelting, deoxidation, screening, alloying, and other operations, to improve product purity and quality.

It should be noted that the process described above is a general lead-zinc ore treatment process, and the specific process parameters and steps may vary depending on the ore and product requirements. In practical applications, it is also necessary to consider the economy, environmental protection, and product quality requirements of the process. Meanwhile, the treatment of lead-zinc ore is a complex process that requires professional personnel and equipment to operate.

PRODUCT PICTURES:

copper concentrate refining electrolysis system anode electrolytic round disc plate casting machine

copper concentrate refining electrolysis system anode electrolytic round disc plate casting machine

copper concentrate refining electrolysis system anode electrolytic round disc plate casting machine

SPECIFICATIONS:

copper concentrate refining electrolysis system anode electrolytic round disc plate casting machine

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy