PRODUCT NAME:

metal polishing machine pool ball polishing machine industrial metal polishing machines

Hexagonal drum polishing machine

Working principle and use of a hexagonal drum polishing machine.

1. Adopting the principle of centrifugal motion, the rust removal, polishing, and deburring periods are short. A cylindrical gear reducer with a speed ratio of 40.17 is used, and the working speed of the drum is between 28-35r/min, which can be completed in about half an hour. Improve work efficiency, save time and effort.

2. The abrasives are mainly river sand and steel sand, which are easy to obtain and cost-effective.

3. * Major advantages: no acid cleaning, dry rust removal oil, polishing, automatic screening, one-time screening, no impurities inside the drum except for small metals.

4. Especially suitable for surface finishing of easily deformed workpieces. After being polished by this type of grinder, the parts not only maintain their original shape and position accuracy, but also improve the surface roughness of the parts by 1-2 levels.

5. Grinding batch parts, medium or large-sized parts, with good results.

6. It has the advantages of low noise and easy operation.

7. The barrel is lined with rubber to prevent workpiece collision, suitable for copper, iron, thin-walled parts, stainless steel parts, etc

8. There is no covered inner lining inside the barrel, which is suitable for materials that are not easily deformed such as steel balls and steel products. Due to the cutting force, it promotes greater effectiveness.

9. It is a simple and convenient model in the grinding machine series, suitable for processing.

10. It can be divided into specifications such as 100-1000L according to its capacity, and can be customized according to needs.

PRODUCT PICTURES:

metal polishing machine pool ball polishing machine industrial metal polishing machines

metal polishing machine pool ball polishing machine industrial metal polishing machines

metal polishing machine pool ball polishing machine industrial metal polishing machines

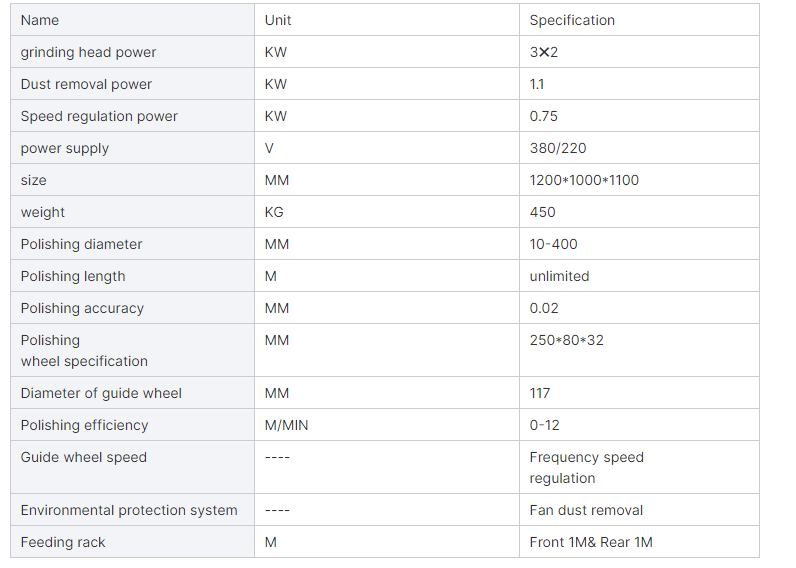

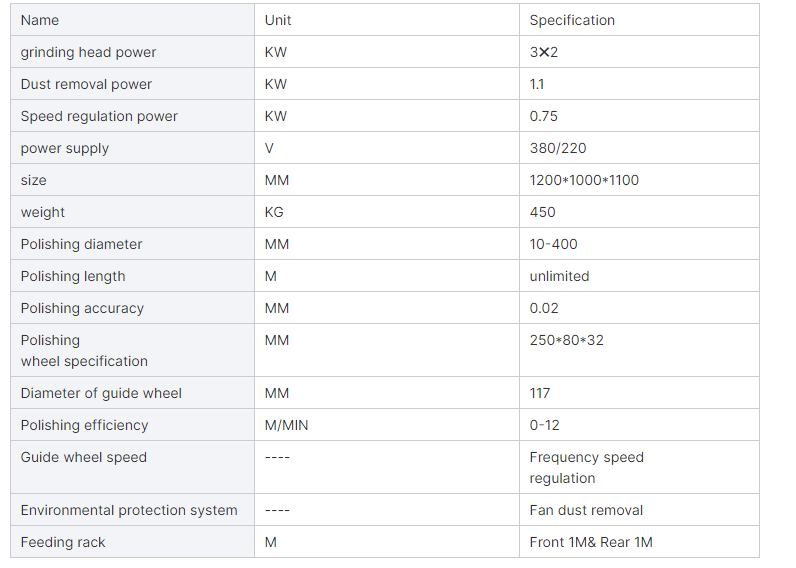

SPECIFICATIONS:

metal polishing machine pool ball polishing machine industrial metal polishing machines

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy