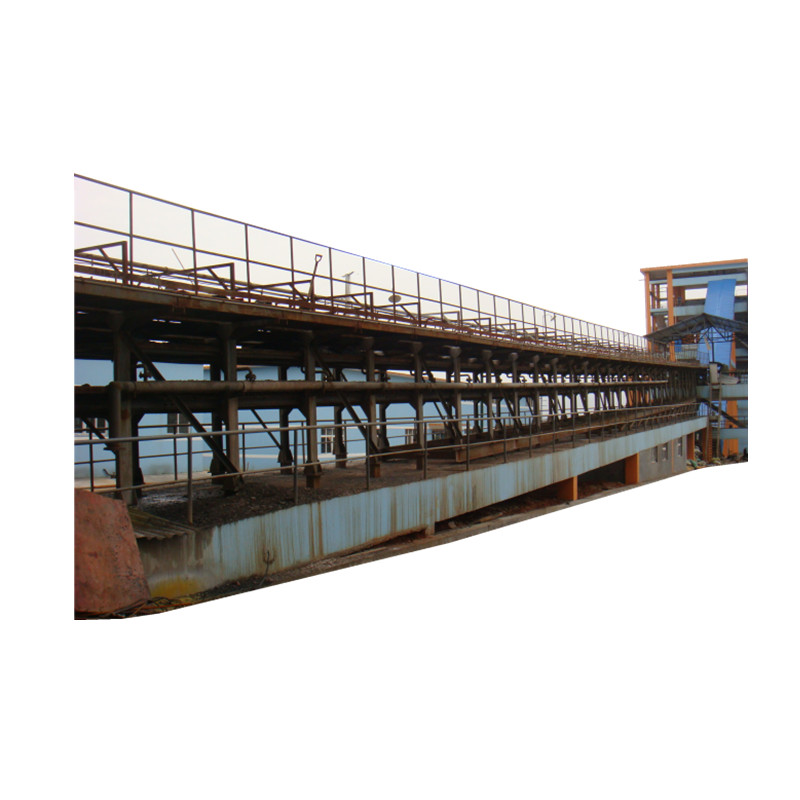

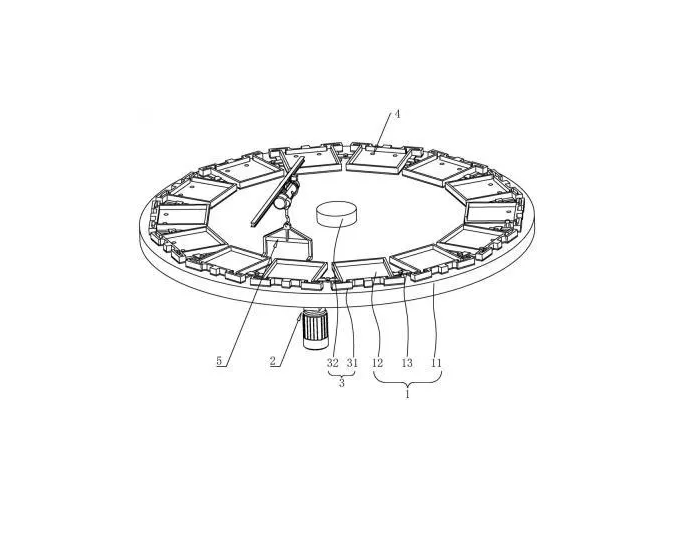

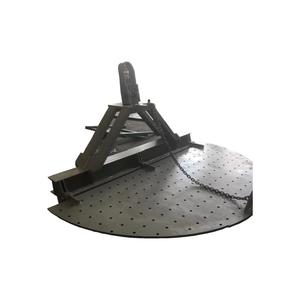

Lufeng company adopts the most advanced Lead Acid Battery Recovery And Regeneration System process at home and abroad. Our core technology is to adopt an automatic crushing and sorting system with high automation, low energy consumption. Lead paste, lead grid and plastic can be selected separately. Then carry out lead paste pre desulfurization treatment, acid purification, crystallization, etc; Finally, the obtained lead paste is put into converter smelting, lead pot refining, ingot casting, etc. The whole process is simple, mature, efficient, energy-saving, environmental protection and other advantages. The waste water in the whole production process can be converted and recycled to achieve the standard discharge of industrial "three wastes".

Lufeng can complete the crushing and sorting of waste lead-acid batteries to the ingot of refined lead, and realize the Lead Acid Battery Recovery And Regeneration System.

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy