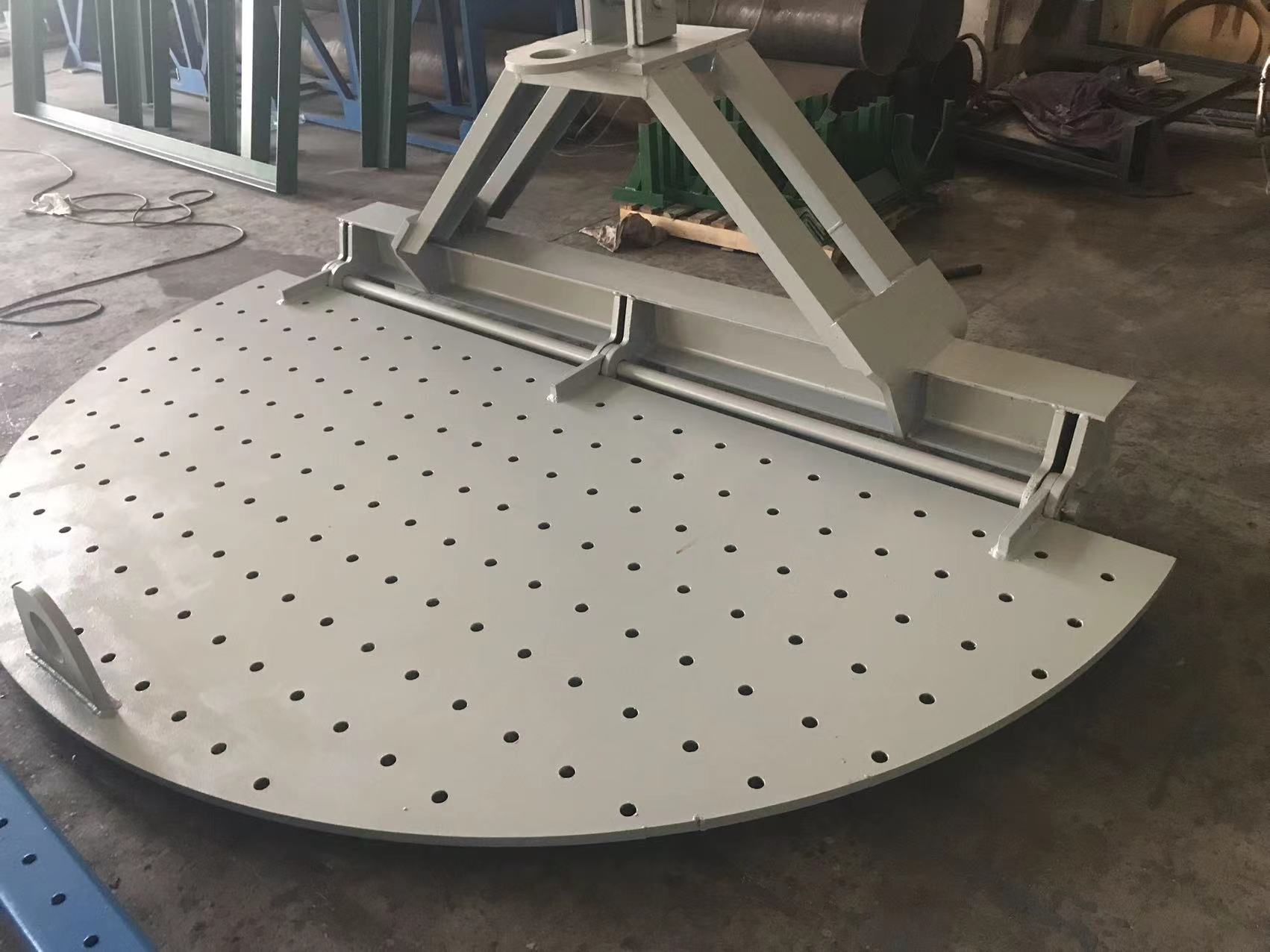

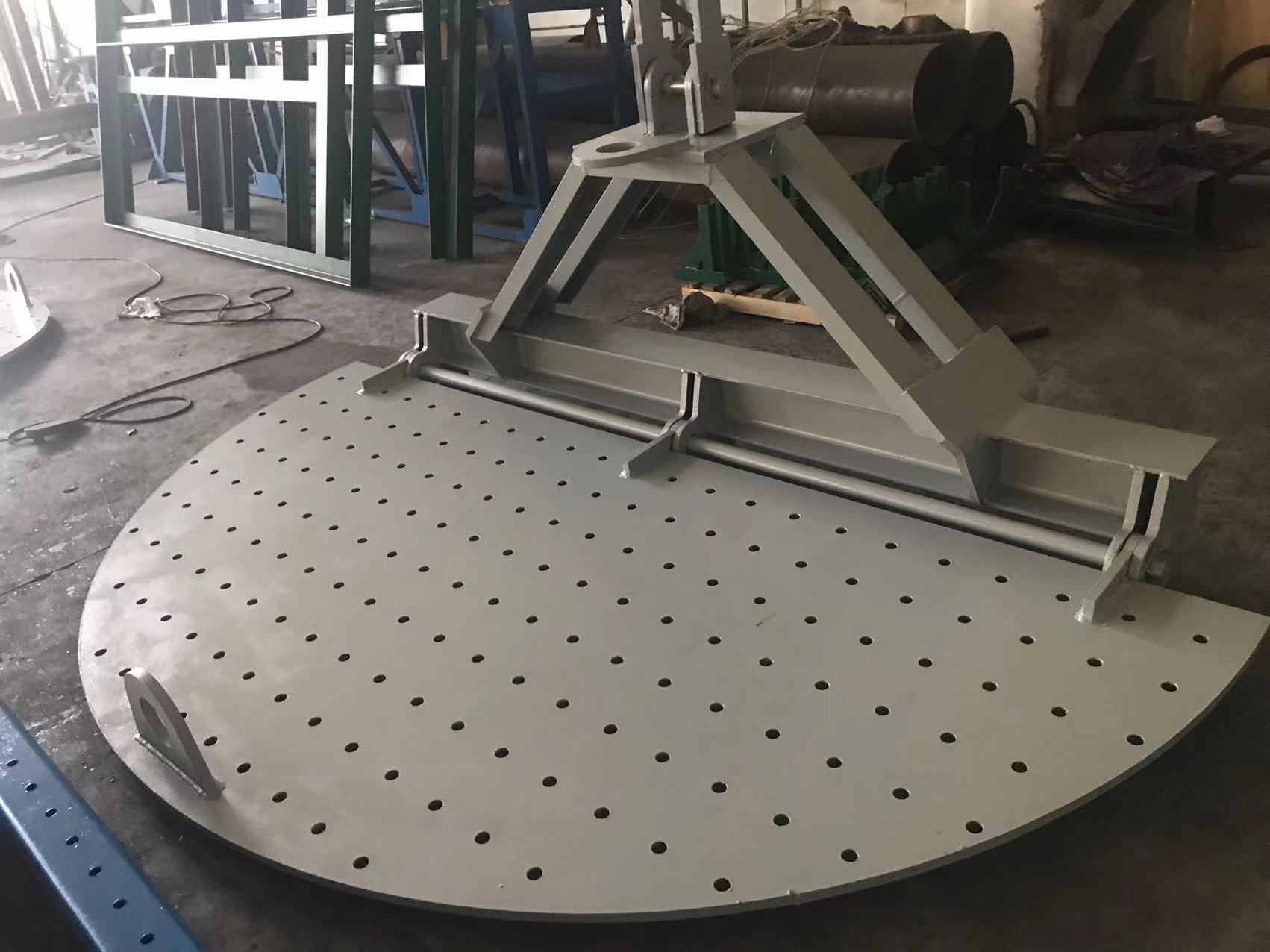

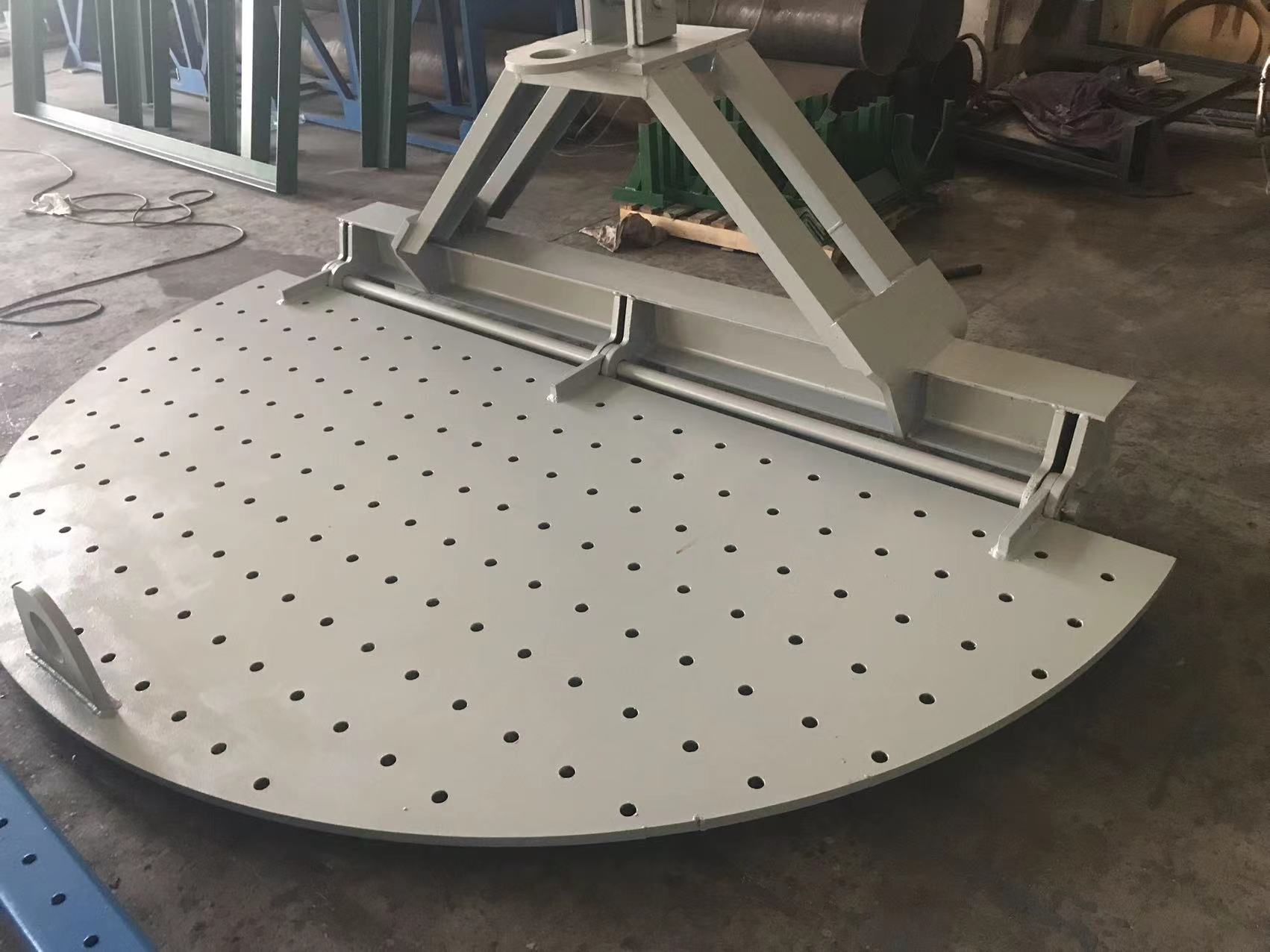

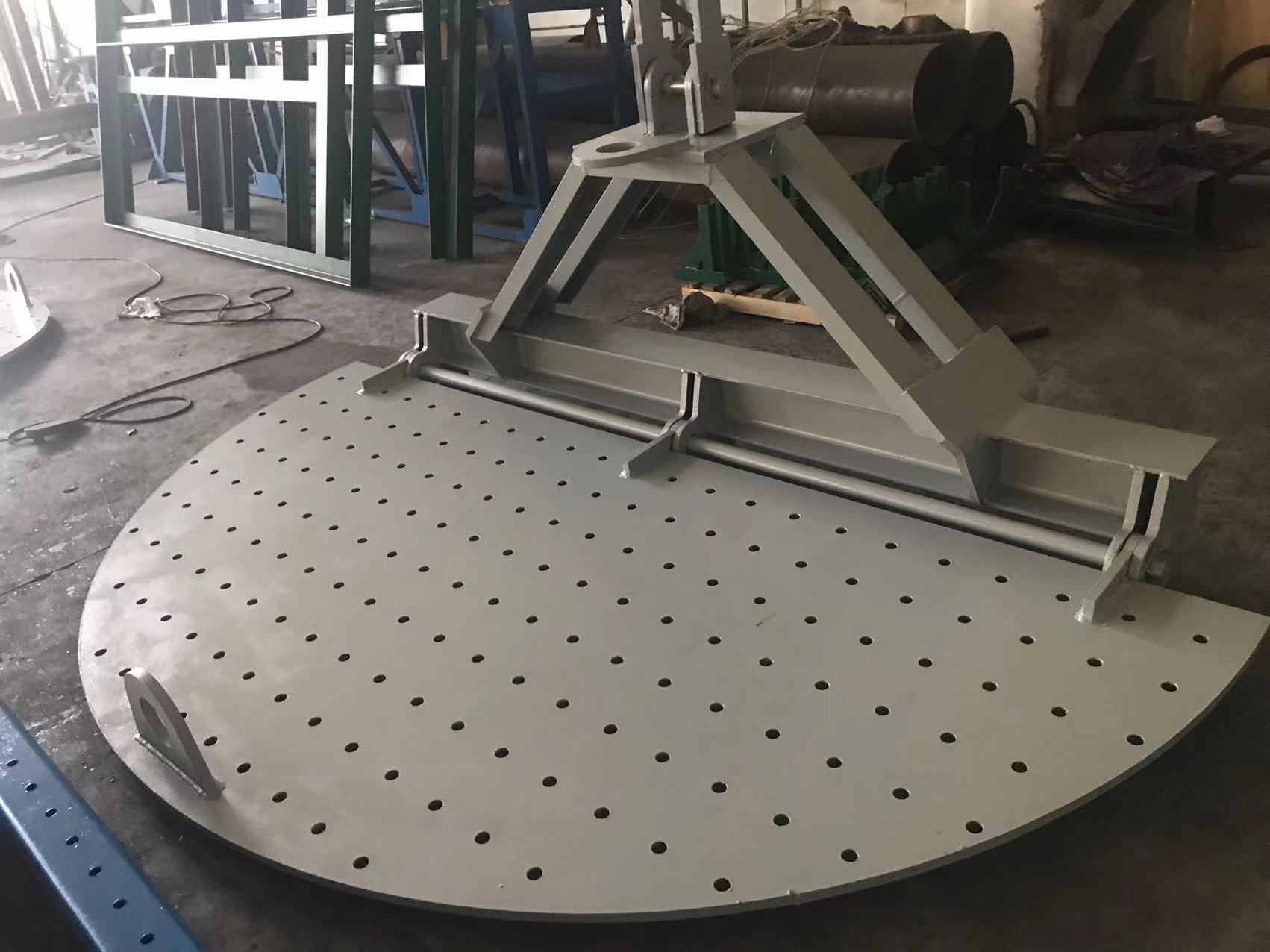

PRODUCT NAME: Slag Salvaging Machine Slag Dragging Machine Semi Automatic Slag Extractor

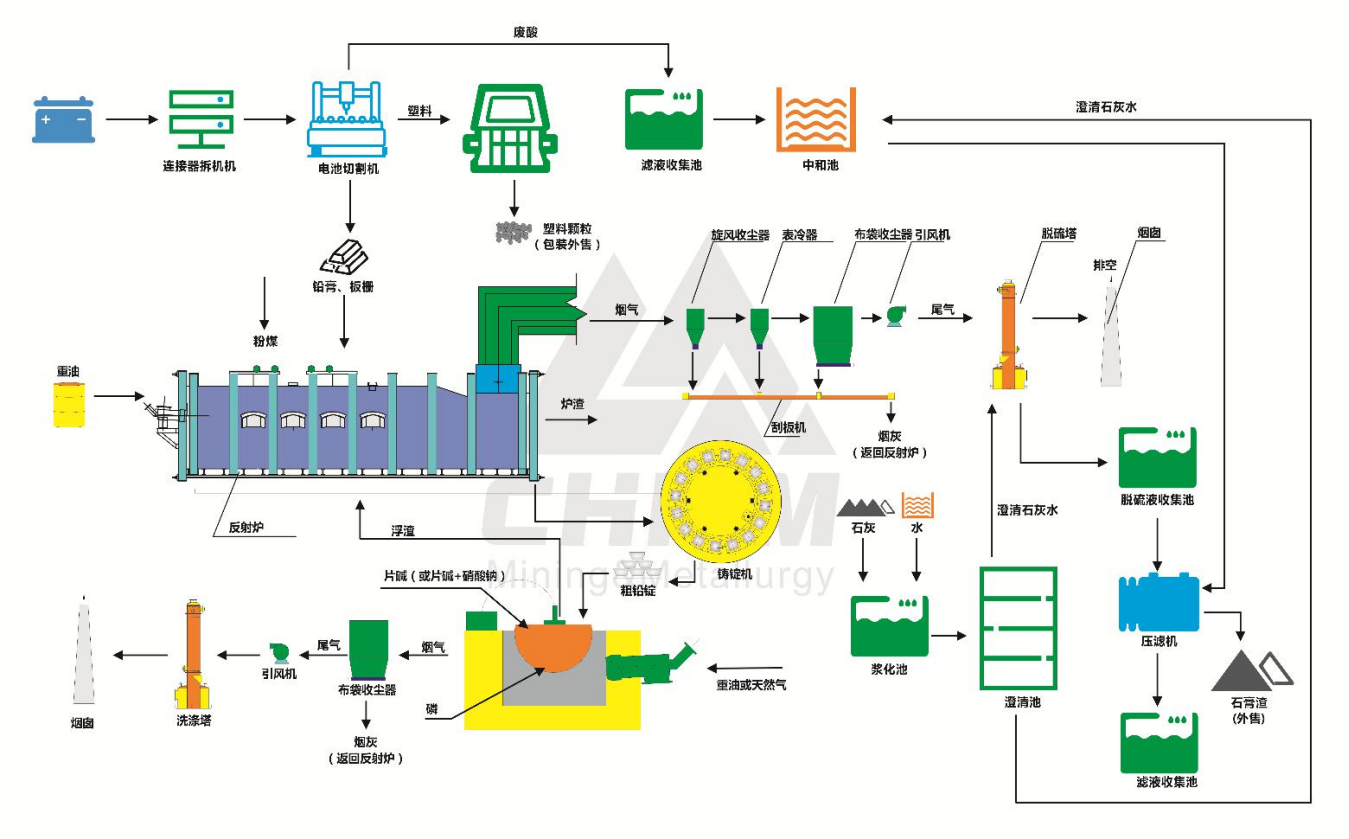

The horizontal groove of the slag extractor is welded from steel plates and profiles, and is divided into two layers: upper and lower. The upper tank is equipped with cooling water, the bottom is paved with wear-resistant steel plate for hot slag cooling granulation, and the lower layer is paved with Diabase wear-resistant cast plate. The upper tank of the slag extractor is generally connected to a closed door to seal the bottom and improve the thermal efficiency of the boiler. The ash scraped by the scraper chain will be discharged through the inclined upward section of the chute to reduce the water content of the slag and ensure that it does not exceed 25%. The upper and lower chutes of the inclined upward section are laid with wear-resistant cast plates, with a service life of no less than 30 years.

PRODUCT PICTURES: Slag Salvaging Machine Slag Dragging Machine Semi Automatic Slag Extractor

SPECIFICATIONS:

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy