China Scrap Anode Brushing Machine factory

China Scrap Anode Brushing Machine manufacturers

China Scrap Anode Brushing Machine suppliers

1. Product Introduction of Plate brushing machine

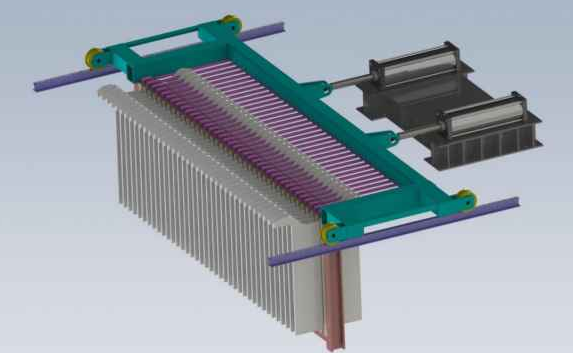

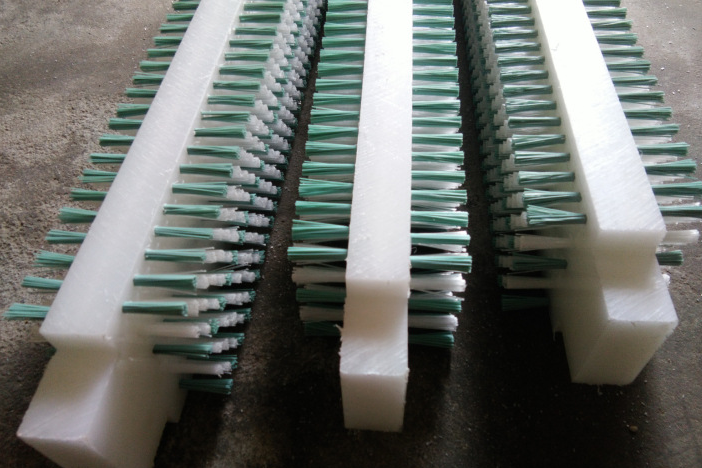

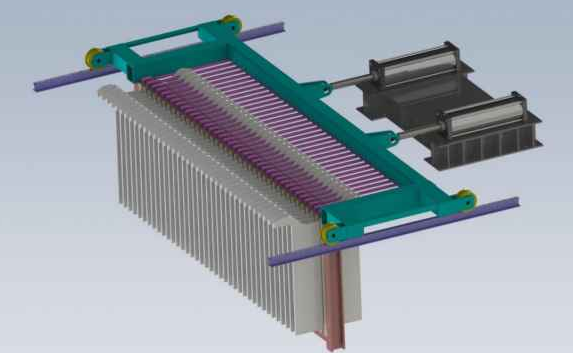

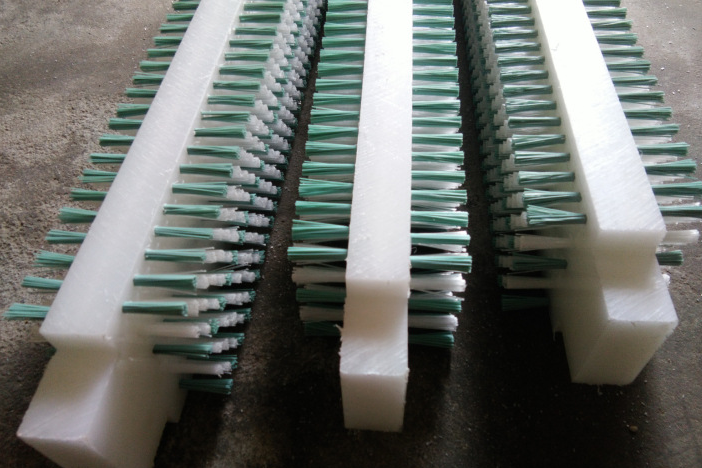

The compound brush plate device is used for the scrap anode brushing machine. The brush structure adopts the latest improved model (the brush has been used in the electrolysis section of many lead smelters at home and abroad for many years, and the washing effect is very good). The brush plate support is made of PVC hard plastic plate, the residual electrode washing machine slot, lower guide pipe, brush support, connecting plate and big crank are made of 1Cr18Ni9Ti material, and the rack and other non immersed mechanisms are made of Q235 and 45 steel The reducer adopts Motor reducer or hydraulic system.

2 .Product Parameter (Specification) of scrap anode brushing machine

|

No.

|

Item Name

|

Parameters / Contents

|

|

1

|

Steel structure material

|

SUS316L/ SUS304/ Q235

|

|

2

|

Drive system

|

Motor reducer / hydraulic cylinder

|

|

3

|

Brush plate material

|

PVC

|

|

4

|

Bristle material

|

Nylon wire or silicon carbide

|

3. Product Feature And Application of scrap anode brushing machine

Scrap anode brushing machine has the following characteristics: corrosion resistance, reciprocating periodic work, simple operation and convenient replacement:

Corrosion resistance, reciprocating periodic operation, simple operation and convenient replacement.

4. Product Details of scrap anode brushing machine

The Scrap anode brushing machine drives the washing rack to make reciprocating motion through the hydraulic cylinder or crank mechanism, so as to achieve the purpose of washing the attachments on the surface of residual electrode. The whole set of equipment has reasonable structure design, high efficiency and easy maintenance. The washing machine shall be used together with the washing tank. The washed anode mud shall be completely collected in the washing tank without secondary pollution and shall be recycled completely. The hydraulic cylinder drives the washing rack to move back and forth. There are bristles on both sides of the residual electrode piece, which can realize the function of brushing. If the attachment of the residual electrode piece is hard, the material of the bristles can be changed to realize the function of brushing. The bristles used at ordinary times are similar to household brushes, with low cost, long service life of half a year, and easy replacement. The bristle plate is inserted in the underframe, so you only need to take it out for replacement.

5. Product Qualification of scrap anode brushing machine

The main parts of scrap anode brushing machine is made of acid and corrosion resistant stainless steel, which can meet the working environment.

6. Deliver, Shipping And Serving of scrap anode brushing machine

Our scrap anode brushing machine adopts integral transportation, which is convenient for customers to install and use on site.

7. FAQ

1). How many years have your company made this kind of equipment?

RE: Since 2010.

2). Do you have detailed and professional installation manual?

RE: We provide detailed installation, operation and maintenance instructions.

3). Are you a trading company or a manufacturer?

RE: We are directly design and manufacturing supplier.

4). Can you can design the equipment according to our size?

RE: Sure. We provide non-standard designed and manufactured equipment.

5). How many staff abroad you sent to install the equipment?

RE: Provide 2-3 engineers to guide installation and commissioning. 1-2 mechanical engineers, 1 Automation Engineer.

6). How many days you need to install the equipment?

RE: The equipment specifications and quantities of each project are different, and the normal single unit lasts about 30 days.

Scrap Anode Brushing Machine factory

Scrap Anode Brushing Machine manufacturers

Scrap Anode Brushing Machine suppliers

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy