Copper lead ingot casting machine

PRODUCT NAME:

copper lead ingot casting machine aluminum cans recycling machine

Aluminum lead ingot casting machine

The aluminum or lead ingot casting machine is composed of a frame, ingot mold, demolding mechanism, main transmission mechanism, water cooling device (or water spray cooling device), aluminum liquid distributor, etc. This machine is not only used for aluminum ingot casting, but also for zinc ingot casting and aluminum based intermediate alloy waffle ingot casting.

The aluminum liquid in the melting furnace flows through the aluminum liquid flow channel to the pouring flow channel and enters the distribution drum of the aluminum ingot casting machine. The distribution drum operates synchronously with the operating speed of the ingot casting machine. The distributor has several evenly distributed aluminum ports, each port aligned with the operating aluminum ingot mold. The flow rate of aluminum liquid during pouring is synchronized with the speed of the ingot casting machine, ensuring the depth of aluminum liquid in the aluminum ingot mold.

This equipment is widely used in manufacturers of aluminum alloy ingots and zinc alloy ingots. It has the characteristics of automatic aluminum water distribution, adjustable casting speed, automatic ingot tapping and demolding, high production efficiency, uniform aluminum ingot weight, no large or small ends, and smooth surface.

The casting process has a high degree of automation and low labor intensity. The casting mold is made of ductile iron, with a long service life、

PRODUCT PICTURES:

copper lead ingot casting machine aluminum cans recycling machine

copper lead ingot casting machine aluminum cans recycling machine

copper lead ingot casting machine aluminum cans recycling machine

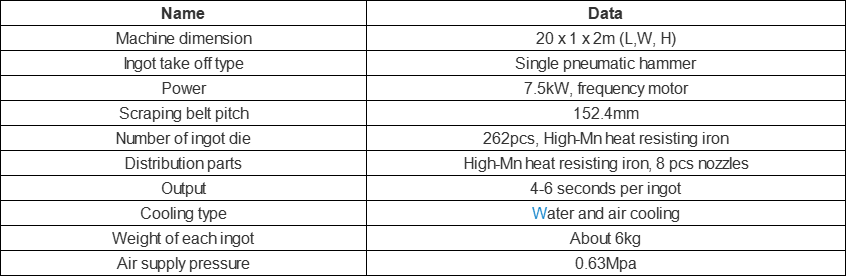

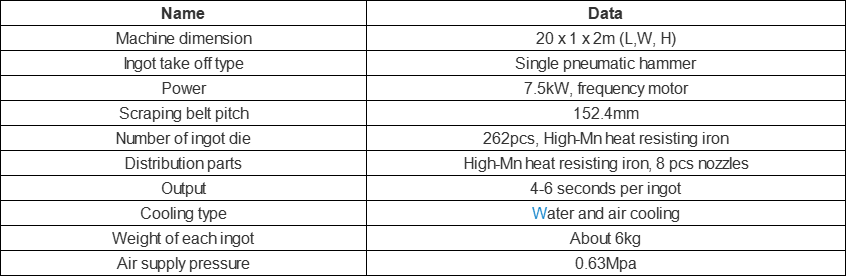

SPECIFICATIONS:

copper lead ingot casting machine aluminum cans recycling machine

aluminum cans recycling machine

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy