PRODUCT NAME: customized Desulfurization tank for recycle metal & metallurgy machinery

Desulfurization technology

The flue gas desulfurization technology, also known as the dual alkali flue gas desulfurization technology, was developed to overcome the disadvantage of easy scaling in the limestone lime method.

There are dozens of types, and according to whether water is added during the desulfurization process and the dry and wet forms of desulfurization products, flue gas desulfurization can be divided into three major categories: wet, semi dry, and dry desulfurization processes. Wet desulfurization technology is relatively mature, efficient, and easy to operate. The traditional limestone/lime gypsum flue gas desulfurization process uses calcium based desulfurizers to absorb sulfur dioxide and generate calcium sulfite and calcium sulfate. Due to their low solubility, scaling and blockage phenomena are easily formed in the desulfurization tower and pipeline.

PRODUCT PICTURES: customized Desulfurization tank for recycle metal & metallurgy machinery

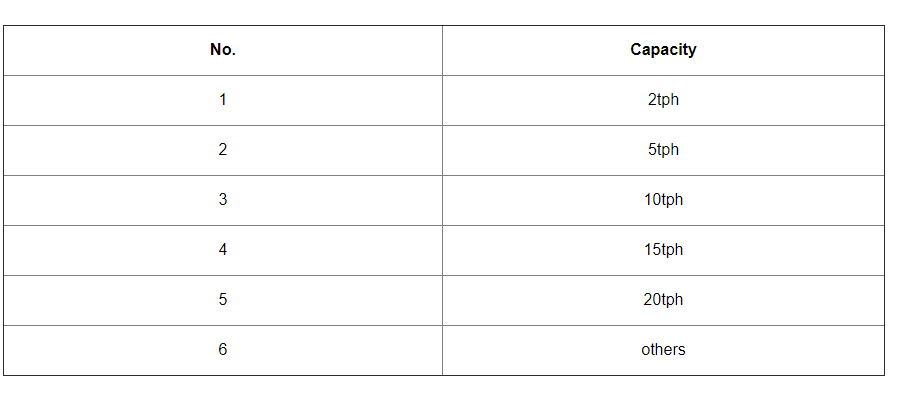

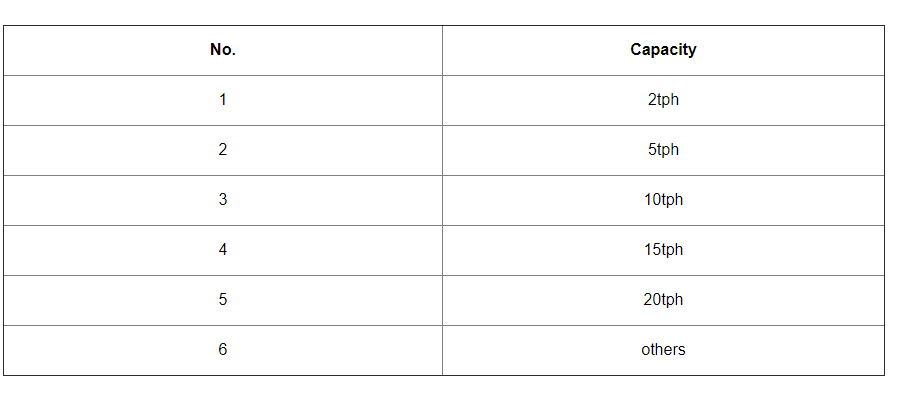

SPECIFICATIONS:

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy