mineral concentrates melting rotary furnace 3 ton rotary furnace lead smelting

Rotary smelting furnace

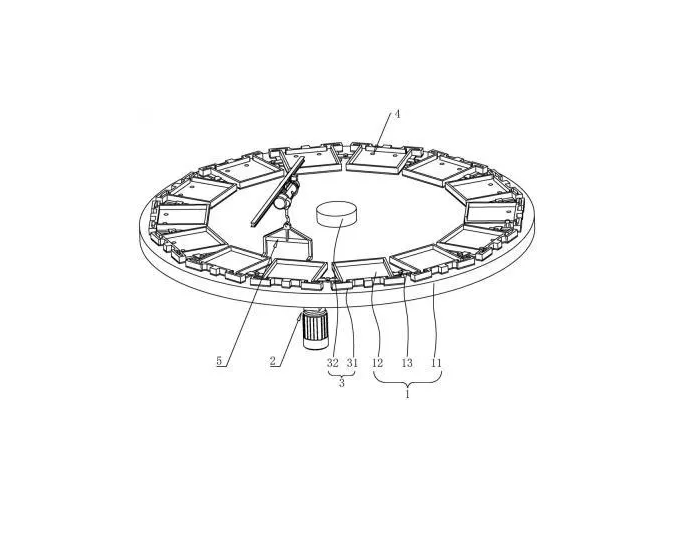

A rotary furnace is a type of blast furnace, whose body is an inclined cylindrical container that can rotate. The principle of rotary furnace is to use the effect of high temperature and high-speed Redox to mix ore and coke together, rapidly heat and melt in the furnace, and separate metal and waste slag.

The internal parts of the rotary furnace are divided into different areas, with the top layer being the combustion zone, where coke and oxygen react to produce high-temperature and high-pressure gas flow. The gas flows downwards and enters the reduction zone. The ore and coke undergo a reduction reaction in the reduction zone, and the metal is reduced out. The metal flows downwards along the furnace barrel and finally reaches the slag area, where it is separated from the waste slag.

The rotary furnace has the advantages of high production capacity and high melting efficiency, and can melt various metal materials such as iron, steel, and alloys. In the steel industry, rotary furnaces have become one of the main steelmaking equipment, widely used in fields such as steelmaking, ironmaking, and scrap recovery.

Lead scraps, Lead grid, Lead acid battery scrap, adaptable to different raw materials.

The Lead melting rotary furnace consists of a rotary host, a fire-resistant furnace lining, a combustion system, a hydraulic system, a Ring gear transmission system and a flue system. Both charging and discharging pass through the furnace mouth installed with a furnace door. During charging and discharging, the furnace door installed with a burner can be opened. Auxiliary machines are equipped with supporting automatic feeding machine, automatic slag (soup) bag and slag raking machine, and automatic ingot casting and stacking machine. Through these supporting equipment, the automatic operation of the whole process can be realized.

Details include:

- Refractory Material of Chrome-Magnesium basis

- air-fuel burner or Oxy-fuel burner or Heavy oil burner

- Feeding door opening through local control panel and through remote control

- Door operation system with hydraulic unit;

- Rotation system 0 - 1 rpm with variable speed driver (by VFD)

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy