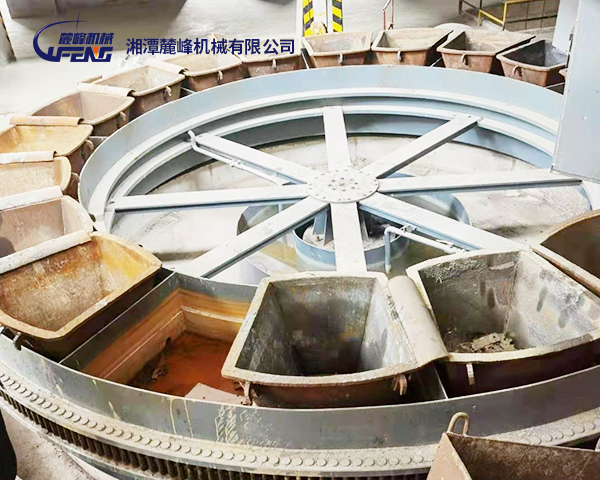

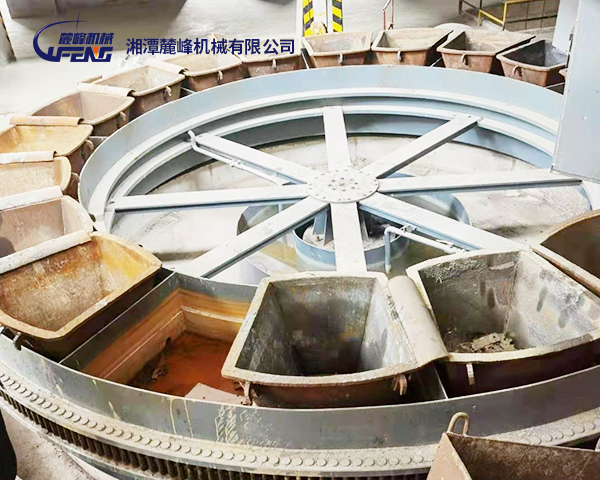

The working principle of the Coarse Lead Disc Ingot Casting Machine:

The Coarse Lead Disc Ingot Casting Machine equipment is mainly composed of a driving device, a disc, a wheel, a track and a mold. The weight of the mold and lead ingot is carried by the track through the wheels. When the equipment is working, operate the electric control button to make the empty mold stop at the casting position. After casting an ingot, operate the button again to make the disc rotate one more mold position, let the next empty mold stop at the casting position, and continue casting. When the casted ingot mold is transferred to the starting position, start the ingot.

After the lead ingot casting machine has been manufactured, it must be assembled in the manufacturing plant and run in an empty run for 2-4 hours. It is required to run smoothly without abnormal noise and vibration. The crude lead disc ingot casting machine equipment is a general contract equipment. The seller is responsible for the production, installation and transportation of the equipment (the installation and commissioning fee is calculated separately), and the buyer is responsible for the basic construction and the provision of total power supply.

Xiangtan Lufeng Machinery Co., Ltd. is mainly engaged in the development, manufacture, installation and commissioning of mining, smelting and construction machinery. Now it mainly produces smelting equipment and complete sets of equipment such as: ingot casting machine, disc ingot casting machine, aluminum ingot casting machine, automatic production line of ingot casting machine, crusher, slag casting machine, mixer, lead and copper and other non-ferrous metal electrolysis complete sets of equipment, lead Pumps, lead boilers and other equipment and upgrades of old equipment. Welcome to inquire and negotiate!

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy