Disc ingot casting machines have been making waves in the metallurgical industry since their introduction in 2022. These machines have revolutionized the way ingots are produced, making the process faster, more efficient, and more cost-effective. In this article, we will explore the benefits of disc ingot casting machines and how they are changing the face of the metallurgical industry.

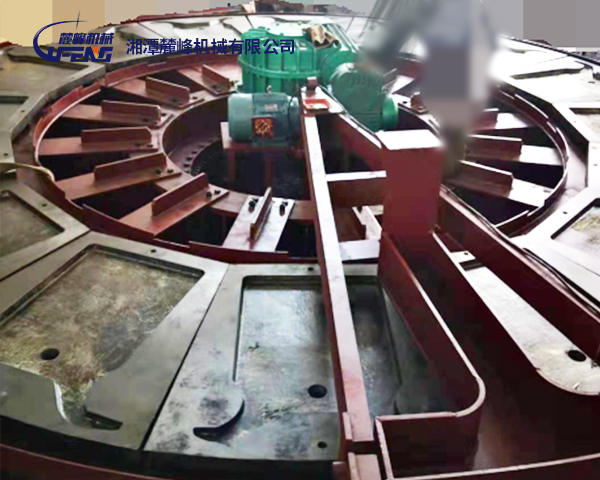

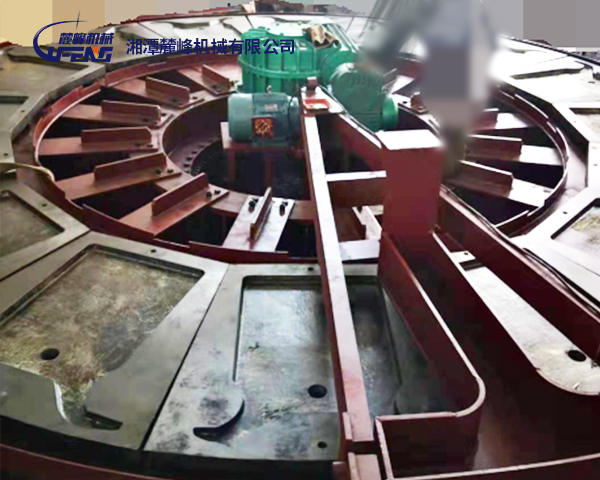

What is a Disc Ingot Casting Machine?

A disc ingot casting machine is a specialized piece of equipment used to produce high-quality ingots. The machine consists of a rotating disc that is used to cast the molten metal into ingots of various sizes and shapes. The disc is made of a high-quality material that can withstand high temperatures and is resistant to corrosion.

Benefits of Disc Ingot Casting Machines

There are several benefits to using disc ingot casting machines, including:

1.Increased Efficiency: Disc ingot casting machines can produce ingots at a much faster rate than traditional casting methods. This means that manufacturers can produce more ingots in less time, which increases their overall efficiency.

2.Improved Quality: Disc ingot casting machines produce high-quality ingots that are free from defects and impurities. This is because the machines use a controlled process that ensures the molten metal is poured at a consistent rate and temperature.

3.Cost-Effective: Disc ingot casting machines are cost-effective because they require less labor and energy to operate than traditional casting methods. This means that manufacturers can produce high-quality ingots at a lower cost, which increases their profitability.

4.Versatility: Disc ingot casting machines can produce ingots of various sizes and shapes, which makes them highly versatile. This means that manufacturers can produce ingots for a wide range of applications, which increases their market reach.

Impact on the Metallurgical Industry

The introduction of disc ingot casting machines has had a significant impact on the metallurgical industry. Manufacturers are now able to produce high-quality ingots at a faster rate and lower cost, which has increased their competitiveness in the market. Additionally, the versatility of disc ingot casting machines has opened up new opportunities for manufacturers to produce ingots for a wide range of applications.

Conclusion

Disc ingot casting machines have revolutionized the metallurgical industry by increasing efficiency, improving quality, reducing costs, and increasing versatility. As these machines continue to gain popularity, we can expect to see more manufacturers adopt them as their primary method of ingot production. The future of the metallurgical industry looks bright with the introduction of disc ingot casting machines.

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy