<p>automatic whole unit scrap lead battery crusher and sorting plate production</p>

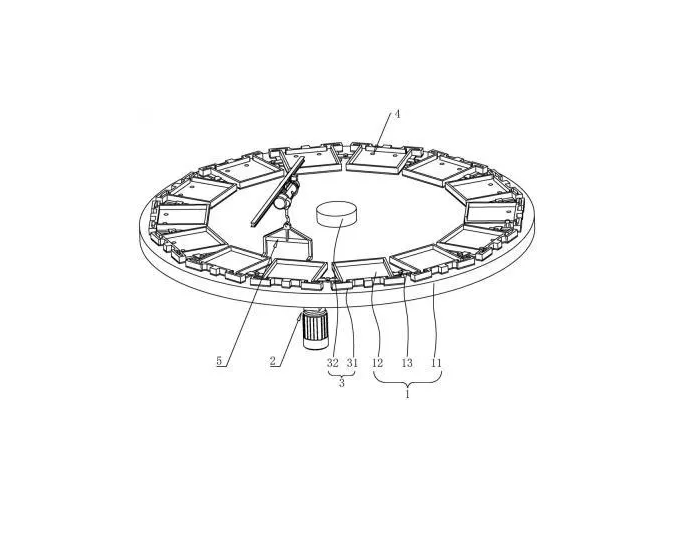

<p>This utility model discloses an automatic crushing and sorting system for waste lead-acid batteries, belonging to the field of waste lead-acid battery recycling and treatment. The system includes a cutting and feeding subsystem, a crushing subsystem, a sorting subsystem, and a pressure filtration and desulfurization subsystem; The discharge end of the cutting and feeding subsystem is sequentially connected to the crushing subsystem, sorting subsystem, and pressure filtration desulfurization subsystem; The crushing subsystem includes: a first stage high-speed rotating thick blade crusher, a crushing water pump, a first stage conveyor, a second stage high-speed rotating thin blade crusher, and a second stage conveyor. Through the cooperation of various systems, accurate sorting of batteries and their upper partitions, various light and heavy plastics is achieved, avoiding high energy consumption and environmental pollution during subsequent processing</p>

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy