<p>non ferrous metal recycle dust collector metal & metallurgy machinery scrap lead battery </p>

<p class="p"><span style="mso-spacerun: 'yes'; font-family: Calibri; mso-fareast-font-family: 宋体; mso-bidi-font-family: 'Times New Roman'; font-size: 12.0000pt; mso-font-kerning: 0.0000pt;">Dust collection system</span></p>

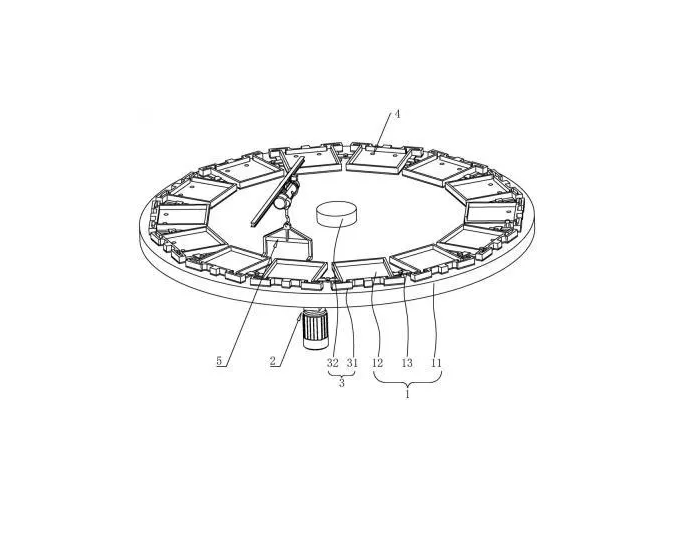

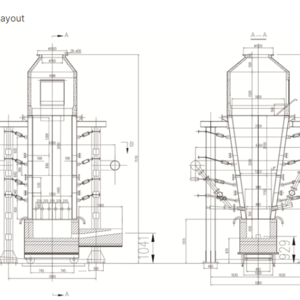

<p class="p"><span style="mso-spacerun: 'yes'; font-family: Calibri; mso-fareast-font-family: 宋体; mso-bidi-font-family: 'Times New Roman'; font-size: 12.0000pt; mso-font-kerning: 0.0000pt;">The main structure of the high-efficiency pulse dust collector consists of several parts, including the upper box body, the middle box body, the ash hopper, the ash unloading system, the spraying system, and the control system. And equipped with basic pillars, ladders, railings, and access doors. Adopting a lower intake structure, the dust containing flue gas enters the ash hopper through the lower part of the middle box through the air inlet. Some larger dust particles directly fall into the ash hopper due to inertial collision, natural sedimentation, and other effects. Other dust particles are filtered by the filter bag as the air flow rises, and are blocked and left on the outside of the filter bag. The purified gas enters the upper box from the inside of the filter bag, and is then discharged into the atmosphere through the air duct and fan through the air outlet. The dust in the ash hopper is regularly or continuously discharged by the unloader.</span></p>

<p class="p"><span style="mso-spacerun: 'yes'; font-family: Calibri; mso-fareast-font-family: 宋体; mso-bidi-font-family: 'Times New Roman'; font-size: 12.0000pt; mso-font-kerning: 0.0000pt;">As the filtration process continues, the dust accumulated on the outside of the filter bag continues to increase, resulting in an increase in the resistance of the bag room dust collector itself. When the resistance reaches the predetermined value (which can be determined during equipment debugging), the ash cleaning controller sends a signal, and then opens the electromagnetic pulse valve to inject 0.4-0.5Mpa compressed air into the box in a very short time.</span></p>

<p class="p"><span style="mso-spacerun: 'yes'; font-family: Calibri; mso-fareast-font-family: 宋体; mso-bidi-font-family: 'Times New Roman'; font-size: 12.0000pt; mso-font-kerning: 0.0000pt;">Compressed air is sequentially sprayed into the filter bag by the air source through the air bag, pulse valve, nozzle on the blowing pipe, and for an extremely short time (0.1-0.2S). Compressed air expands at high speed inside the box, causing high-frequency vibration and deformation of the filter bag. In addition, the effect of reverse airflow causes the dust on the outside of the filter bag to fall off.</span></p>

<p class="p"><span style="mso-spacerun: 'yes'; font-family: Calibri; mso-fareast-font-family: 宋体; mso-bidi-font-family: 'Times New Roman'; font-size: 12.0000pt; mso-font-kerning: 0.0000pt;">After ensuring that the dust falls off, open the next electromagnetic pulse valve for such a cycle. During ash cleaning, each solenoid valve is operated in a pre-set sequence without interfering with each other, achieving long-term continuous operation. For industries and mines with uncertain dust content, dust collectors can be used to achieve dust removal through resistance.</span></p>

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy