Lufeng is a Professional metallurgical Blast furnace’s design, manufacturing and sales manufacturers in China. We have been specialized in Metallurgical equipment for many years. The Blast furnace is widely used for the lead /copper/zinc ore melting plants all over the world.

There are rectangular and oval sections of Blast furnaces. The water jacket at the end of the oval furnace is semicircular, which is difficult to process, but the furnace gas is evenly distributed in the furnace. Generally, oval furnaces are used for small furnaces, and rectangular furnaces are used for large factories.

Due to the existence of central material column in the closed blast furnace, the resistance to blast is large, and the height of material column is limited. The effective height of the furnace, that is, the height from the central plane of the tuyere to the top surface of the charging bucket, is generally not more than 4~4.4m. Therefore, the increase of the size of the furnace cannot increase its height, but only its cross-sectional area. The width of the tuyere area of the blast furnace is generally fixed at 1.1~1.2m, and the blast pressure needs to be increased to increase the width. Therefore, the sectional area of the tuyere area of the furnace only depends on the length, and the length of the furnace mainly depends on the productivity. In principle, there is no limit on the length of the closed blast furnace, but the furnace is too long to take care of, so the length of the blast furnace is generally 2~9m.

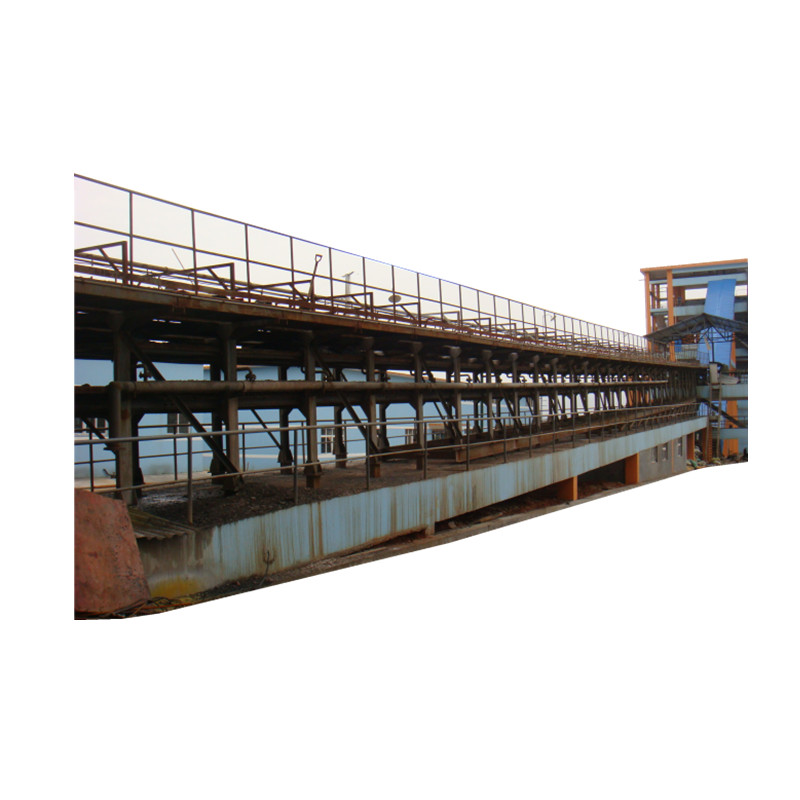

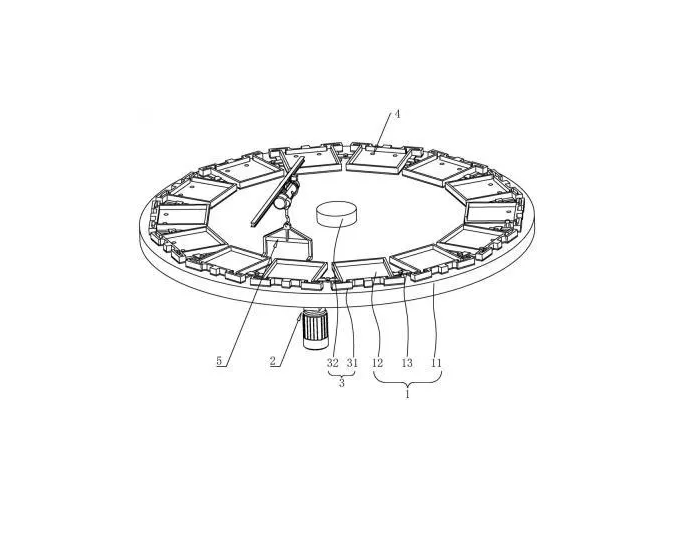

The foundation of the closed blast furnace is poured with concrete, and several supports are set on the foundation or the side wall of the jack is assembled with several water jackets. The water jackets are bolted and fixed on the special support, and the furnace top charging bucket and brick masonry are supported on the surrounding pillars through horizontal steel beams. There is a vent at the lower part of the side water jacket for blowing air. The lower end of the front-end water jacket is equipped with a furnace mouth, namely a throat, from which matte and slag melts are discharged and injected into the front bed through the launder.

Our company can produce full water jacket or half water jacket blast furnace, and the cooling mode can be vaporization cooling or water cooling. The commonly used blast furnace is 0.6m², 1.2m², 2.0m², 2.6m², 3.4m², 6m², 8m², 10m² And other specifications.

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy