Lufeng is the design and equipment supplier of lead electrolysis system. It has provided design and related equipment for many lead smelters at home and abroad.

The purpose of lead electrolysis system is to obtain high purity industrial lead and recover the associated bismuth and rare precious metals. Most of the raw materials for lead electrolysis are mineral crude lead, and the rest are recycled lead and crude lead, a by-product of tin smelting. Before electrolytic refining of crude lead, copper or tin in crude lead should be removed by Pyrorefining in advance, and the content of antimony should be adjusted, and then cast into anode plate for electrolysis. At present, we mostly use silicofluoroate electrolysis.

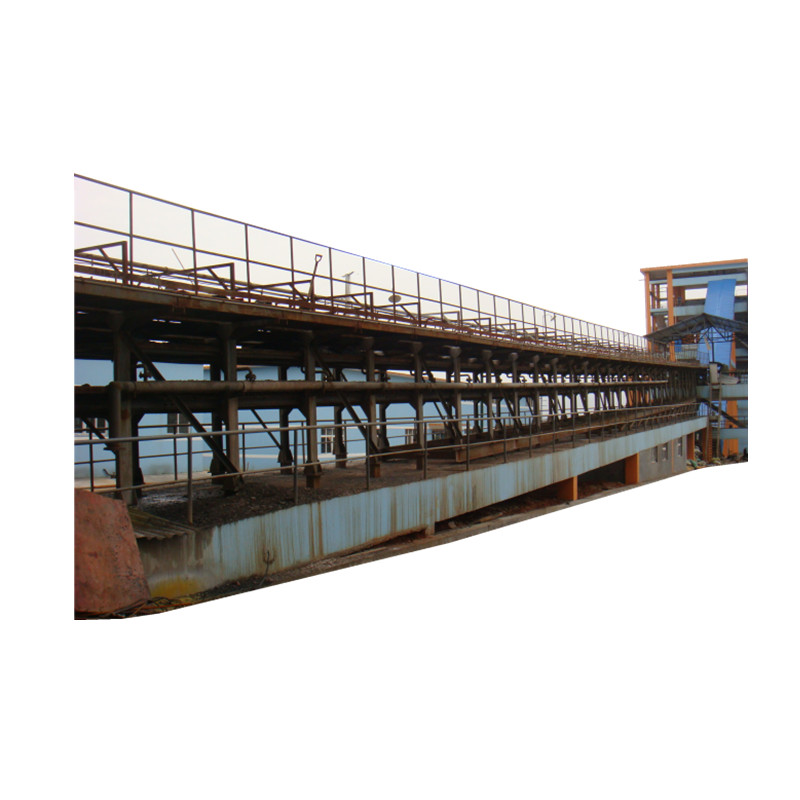

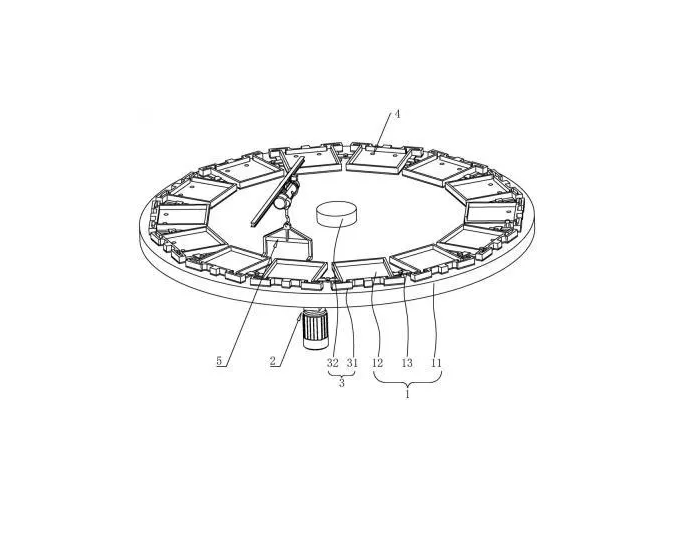

The main equipment of the lead electrolysis system mainly includes: Starter plate unit, anode disc casting machine, electrolytic cell, conductive copper bar, rectifier, anode mud treatment system, electrolyte preparation system, etc.

Lufeng has a mature design team, which can design the electrolysis workshop according to the specific project requirements of customers. Build a modern smelter with energy conservation, good economic efficiency and environmental friendliness for customers.

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy